class 100 clean room is defined as

A cleanroom or clean room is an engineered space which maintains a very low concentration of airborne particulates. Class 100 area is defined as area where there should not be more than 100 particles of 05 micron per cubic foot of air.

Clean Room Classifications Iso Standards Quotes 48 Hours

Therefore when an inspection needs to be done or work performed on the inside of a hard drive then it needs to be done in a Class-100 or better clean room.

. Class 10 must have. Parameters that are evaluated include filter. The standard also allows interpolation so it is possible to describe eg.

A Class 5 room can have an air change rate of 400 to 600 times per hour while a. The equivalent FED standard is class 10000 or 10000 particles per cubic foot. A simple definition of this would be the opposite of my bedroom But technically speaking a clean room is a highly purified and regulated room for producing equipment.

Clean room and clean air device classification in relation to GMP 2008. A Class 1 clean room for example is defined by the number of allowable particles per cubic foot of air in this case no more than 35 particles of 01 m in diameter. A controlled environment such as a clean zone or clean room is defined by certification according to a relevant clean room operational standard.

Large numbers like class 100 or class 1000 refer to FED_STD-209E and denote the number of particles of size 05 µm or larger permitted per cubic foot of air. Maximum permitted number of particles m³. Class 1000 defined same where there should not.

Grade A this defines the local zone for high-risk operations like filling zone stopper bowls open ampoules and vials and making aseptic connections. Not more than 120 per cubic foot of 05 im. These class 100 clean room companies can design engineer and manufacture class 100 clean room to your specifications and application need.

A Class 5 room can have an air change rate of 400 to 600 times per hour while a. A class 10 clean room is allowed no particles greater than 5 microns less than 10 particlesft3 greater than 05 um and less than 30 particlesft3 great than 03 microns. An ISO 6 clean room Class 1000 cleanroom is a soft- or hard-sided wall manufactured structure that utilizes HEPA filtration systems to maintain air cleanliness levels of a maximum of 1000.

Class 100 clean room is defined as a room in which theparticle count in the air is. A cleanroom must have less than 352000 particles 05 micron per cubic meter and 60HEPA filtered air changes per hour. USP 800 Cleanroom Hazardous Drugs HazCom Clean Room Designations Cleanroom.

Class 100 clean room is defined as a room in which theparticle count in the air is. Up to 4 cash back How to clean a Class 100 ISO Class 5 Cleanroom. Class 100 area is defined as area where there should not be more than 100 particles of 05 micron per cubic foot of air.

The clean room class is the level of cleanliness the room complies with according to the quantity and size of particles per cubic meters of air. We use laminar flow technology in our clean room. The maximum allowable particles for particles for a Class 10 Cleanroom are below.

Not more than 100 per cubic of 05 im and larger in size. ISO 8 cleanrooms also known as Class 100000 cleanrooms can be modular or soft-walled and have a maximum particle count of 100000 particles 05 um per cubic foot of interior air. The ISO 7 is a common clean cleanroom classification.

A properly designed clean room must have a high rate of air changes to scrub the room of particulates. A Class 100 CLEAN ROOM is a laboratory that has a controlled level of airborne particles and controlled parameters such as humidity temperature and pressure etc. The equivalent FED standard is class 1000 or 1000 particles per cubic foot.

Product videos and product information. The primary authority in the US and Canada is the. ISO 8 cleanrooms also known as Class 100000 cleanrooms can be modular or soft-walled and have a maximum particle count of 100000 particles 05 um per cubic foot.

The probably most important requirement is the airborne particulate cleanliness class. A properly designed clean room must have a high rate of air changes to scrub the room of particulates. It is well isolated well-controlled from contamination and actively.

This is classified by specifying the maximum permitted number of airborne particles and divided into. At ACS Data Recovery we utilize a.

Iso 8 Cleanroom Specifications Iso Clean Room Standards

What Is A Cleanroom Cleanroom Classifications Class 1 10 100 1 000 10 000 100 000 Iso Standard 14644 Cleanroom Definition

Three Posts Rhinebeck 75 Recessed Arm Sofa Fabric Gray 100 Linen Modern Furniture Living Room Living Room Style Living Room Furniture

10 Beautiful Full Length Mirrors Under 100 House Interior Bedroom Decor Living Room Inspiration

What Is A Cleanroom Cleanroom Classifications Class 1 10 100 1 000 10 000 100 000 Iso Standard 14644 Cleanroom Definition

Portafab What Is A Clean Room Cleanroom Design Classification

What Is A Cleanroom Cleanroom Classifications Class 1 10 100 1 000 10 000 100 000 Iso Standard 14644 Cleanroom Definition

Clean Room Classifications Iso Standards Quotes 48 Hours

Clean Room Manufacturers Clean Room Modular Walls Glass Panels

What Is A Cleanroom Cleanroom Classifications Class 1 10 100 1 000 10 000 100 000 Iso Standard 14644 Cleanroom Definition

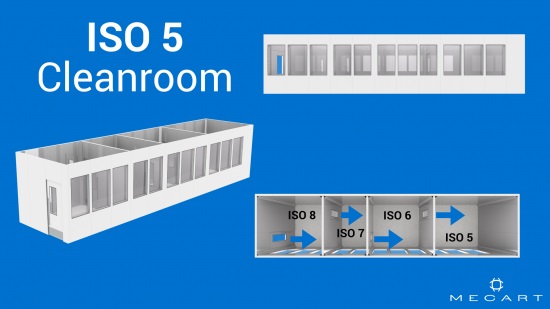

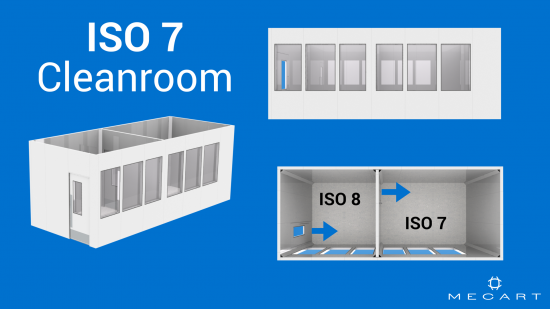

Clean Room Classifications Iso 8 Iso 7 Iso 6 Iso 5 Mecart

What Is A Cleanroom Cleanroom Classifications Class 1 10 100 1 000 10 000 100 000 Iso Standard 14644 Cleanroom Definition

Clean Room Classifications Iso Standards Quotes 48 Hours

Iso 8 Cleanroom Specifications Iso Clean Room Standards

Portafab What Is A Clean Room Cleanroom Design Classification

Clean Room Classifications Iso 8 Iso 7 Iso 6 Iso 5 Mecart